Important information regarding calls for tenders

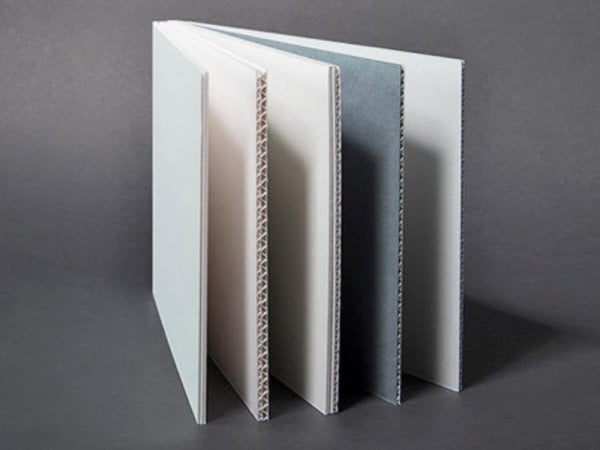

KLUG-CONSERVATION has been producing corrugated board made from ageing-resistant paper since 1994. Over the years, KLUG-CONSERVATION managed to become the market leader for corrugated board based on the technological requirements of DIN EN ISO 9706 and DIN ISO 16245 – Type A. Since 2003 – partly in response to the Elbe River flooding in Saxony – all corrugated boards used to make boxes and folders are laminated with wet-strength adhesive.

In 1996, the term “Sortenwahrheit” (approximating to “full disclosure of materials” in this context) was coined by Prof Dr Guido Dessauer in a number of important talks and articles in specialist magazines. The term refers to honesty when specifying the materials used for making ageing-resistant products, as well as completeness of technical information required for quality assessment of a material.

Over the past years, other companies have also started to produce and offer ageing-resistant corrugated boards. Unfortunately, not all competitors state or disclose the factors required for assessment of quality and price.

When comparing the offers of various manufacturers, the questions that arise are: what makes up the price of a corrugated board and which criteria determine the quality of a corrugated board? In order to meet the quality characteristics in accordance with EN ISO 9706 and DIN ISO 16245 – Type A, all products for long-term storage must be fabricated from 100% primary fibre without using any recycled fibre, which is imperative for fulfilment of point 5.1 of EN ISO 9706.

Fresh cellulose fibre is traded on the world market like crude oil. We are familiar with regular information regarding the price of crude oil that immediately makes us think about our next trip to the petrol station and the fuel prices there. It’s a similar scenario for the price of fresh pulp fibre.

The price of paper products can be determined quickly by looking at the pulp price index. The three main resources for the production of paper are fibre, water and energy. The production costs (paper machine, staff, transport etc.) barely fluctuate. At approx. 56%, the fibre constitutes the biggest part of the costs. A price comparison of different offers should therefore always include grammage as an essential parameter.

On a percentage basis, the price of a single-layer corrugated board is made up as following:

56% material content = fibre content = cellulose

23% production of the corrugated board

6% glue

3% wet-strength finish

12% pallet, packaging, transport

Manufacturers of ageing-resistant corrugated board aim to achieve a competitive advantage through savings in the production process. These savings usually involve a decrease in quality. Examples for this include:

- While reducing the grammage of corrugated board or its individual layers results in the biggest economic advantage, it also has a major impact on the strength of the corrugated board and the boxes, folders and other items produced from it.

- Omission of wet-strength finish of corrugated boards also leads to a significant price advantage. Corrugated board without wet-strength finish should under no circumstances be used for the storage of cultural goods.

- The use of short-fibred papers, possibly also secondary fibres, also produces a price advantage, while at the same time decreasing stability.

It is sometimes also attempted to prevent comparability of different products or manufacturers by non-disclosure of technical parameters. For example: a supplier only specifies the thickness of a corrugated board, while withholding information about the grammage of the individual layers or the entire laminate.

For proper assessment of an ageing-resistant corrugated board with regard to quality, and for the sake of fair competition, suppliers should at least specify the above-mentioned technical parameters and provide confirmation by means of a legally binding quality guarantee, in line with the concept of “Sortenwahrheit” (approximating to “full disclosure of materials”). A comparison of different offers can only be meaningful if all of the named parameters are provided. A merely price-based assessment will eventually lead to a decrease in the quality of ageing-resistant corrugated board and the protective packaging made from it.

Materials for long-term conservation must meet the technological requirements of the EN ISO 9706 and DIN ISO 16245 – Type A. To make sure that the material you are buying complies with these standards, you should always request a legally binding, signed quality guarantee, irrespective of tests carried out in the past. Products for archiving photographs are additionally required to have passed a Photographic Activity Test (PAT) in accordance with ISO 18916:2007. For more information please visit our website.

The following aspects can be considered for assessment of the quality of an ageing-resistant corrugated board:

- Fibre quality

- Papers with a higher content of long fibres result in corrugated boards with higher strength

- Papers made from primary fibres produce corrugated boards with higher strength

- Grammages of individual layers of corrugated board

- Higher grammages (in accordance with DIN ISO 3039) of the component layers result in corrugated boards with higher strengths

- Outer layers with higher grammages lead to higher puncturing resistances (puncture resistance in accordance with DIN 53142)

- Total grammage of finished corrugated board

- The total grammage (in accordance with EN ISO 536) is the sum of the grammages of all layers including the weight of the introduced glue

- Higher total grammages of the corrugated board result in higher strengths

- Thickness of individual layers of corrugated board

- Thicker paper layers make for corrugated boards with higher strength

- Surface density of corrugated board layers

- The layers should have a surface density (Cobb 60) <=25

- Test in accordance with EN 20535

- The denser the layers, the longer the resistance to humidity or water in the event of damage

- Cover layer finishing

- Cover layer fully dyed or printed?

- Fully dyed cover layers are smoother and more erasable

- Flute height of corrugated board

- Bigger flute height leads to higher compressive strength (flat crush resistance in accordance with EN ISO 3035), however to lower edgewise crush resistance (edgewise crush resistance in accordance with EN ISO 3037) and lower puncture resistance (puncture resistance in accordance with DIN 53142)

- Wet strength

- Wet-strength glued layers of corrugated board in accordance with DIN 53133 guarantee at least 24 hours of water resistance of the glue bond

- Wet-strength glued layers of corrugated board prevent the layers of a corrugated board from falling apart and hence the loss of “units” in case of water damage; boxes made of corrugated board without wet-strength glued layers disintegrated in a short period of time and lose their stability

- Bleeding resistance

- The layers of corrugated board must not bleed colour in the event of water damage

- Test in accordance with DIN ISO 16245

- Optical brightening agents

- The layers of corrugated board should not be optically brightened

- Test in accordance with DIN ISO 16245

PS How can grammage be calculated?

The grammage of a paper, cardboard or corrugated board can be calculated easily. A rectangular sample is cut and then weighed on a paper scale. For thinner papers, a number of papers with the same format or a large folded sheet can be used for precise determination of weight. Grammage is calculated as the ratio of weight and area. Example: a 10 x 10 cm piece of cardboard weighs 3 g. The grammage of the cardboard is therefore 3 g / (0.1x0.1) m² = 300 gsm..

Further information on this topic can also be found in our new Technical Knowledge 9 – A comparison of corrugated boards Knowledge9